Your challenge

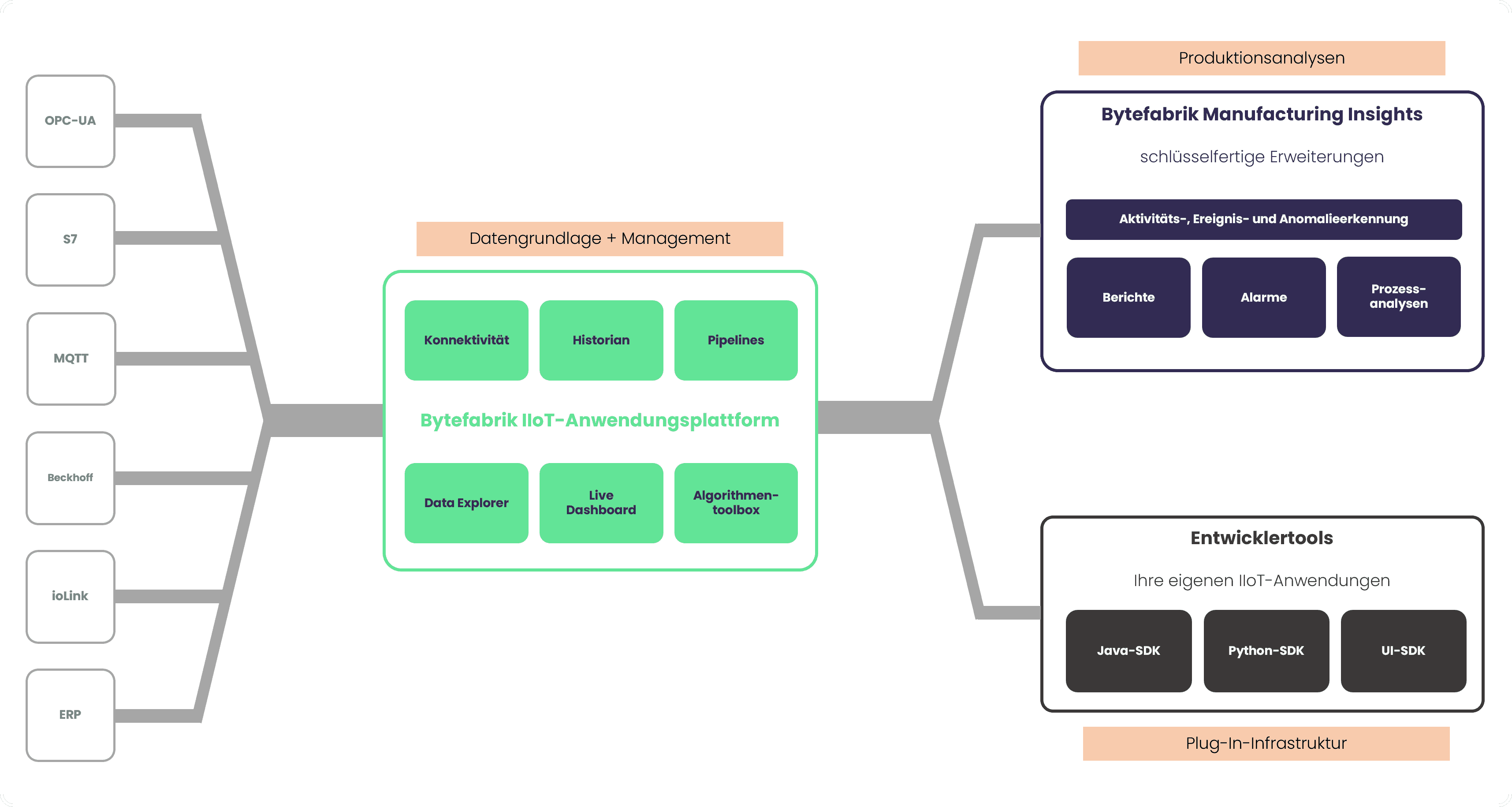

Our software supports you with challenges at the interface between Operational Technology (OT) and Information Technology (IT) with innovative software solutions and by using machine and process data.

Your challenge from an IT perspective

Build and operate IIoT infrastructure

Develop IIoT solutions

Your challenge from a production perspective

Gain transparency and understand problems

Improve production efficiency and product quality

Manufacturing Intelligence

Bytefabrik IIoT-Anwendungsplattform

Your flexible solution for building your machine and process data analytics and IIoT application development infrastructure.

Bytefabrik Manufacturing Insights

Efficiency boost for your production through 360-degree analysis of all equipment, stations, processes and process parameters.

Data-driven decision support

Our software uses live machine data, which is already available in your plant, to improve plant productivity.

Process transparency

You have never experienced key figures like this before: Explore processes per plant, station and activity and conveniently navigate from error to cause to elimination.

Comprehend problems

Our system monitors process and sensor data in real time and sounds the alarm when problems occur - along with an intuitive explanation of the cause.

Increase efficiency

More than 100 preconfigured algorithms for data analysis and fault detection - and if they don't find something, just teach our AI a new task yourself.

Open source basis

Open source has many advantages. You avoid lock-in effects, can extend your solution independently and rely on quality-tested software.

For these reasons, open source has long been accepted in the IT environment.

We are now bringing these benefits to the industry: as a true open source company, we are the initiators of Apache StreamPipes, an open solution for IIoT data analytics. We don't just talk about open source, we take the initiative and invest substantial development capacity in open source development.

As a customer, you benefit from an open solution and still enjoy all the advantages with us, such as commercial support and innovative add-ons that save you your own investment costs. Let us convince you!

Why Bytefabrik.AI

Bytefabrik.AI, based in Karlsruhe, is a successful technology spin-off of the Karlsruhe Institute of Technology (KIT) and the FZI Research Center for Information Technology. After intensive research work, we have been developing intelligent AI-based software solutions with a focus on intuitive usability for more than 10 years.

Our goal: We want to inspire our customers and users - guaranteed!

Learn moreMultiple Awards